Consulting-first

AI-Driven Materials & Process Consulting

We deliver decision-grade analyses, experiment strategies, and engineering reports that help materials and process teams move faster without compromising scientific rigor.

Services

Consulting with engineering-grade outputs

We work with R&D and manufacturing teams to UNDERSTAND complex systems, ACT through targeted experiments, and RESOLVE critical decisions with engineering-grade analysis.

Decision-Grade Analysis

Clarify system behavior, key drivers, and decision trade-offs before experiments.

- Assumptions & scope framing

- Key drivers & system behavior

- Decision trade-offs & risk framing

Execution Strategy

Translate validated insights into targeted experiments and actionable engineering steps.

- Experiment or simulation strategies

- Operating ranges or field predictions

- Engineering recommendations

Root Cause & Resolution Support

Resolve root causes by isolating dominant drivers and defining validation paths.

- Evidence map

- Hypothesis tree

- Targeted validation plan

Capabilities

Caldera: AI Process Map Explorer

Caldera is our internal AI workflow engine—a structured consulting capability that explores process maps and supports engineering decisions under limited data, combining AI-assisted analysis with expert review.

- AI models infer process maps from sparse experimental coverage, with uncertainty-aware and goal-oriented recommendations

- Retrieval-augmented generation (RAG) integrates domain literatures and established physical and chemical formulas

- Runs entirely with local models on client-provided data, with no data upload or leakage

*For sensitive projects, Caldera workflows can be executed within client-controlled environments to support data confidentiality requirements.

Process Mapping

What it is

An internal AI workflow engine for process map modeling and decision reporting

When to use

Multivariate process problems with sparse experimental coverage where trial-and-error is costly

What you get

Decision-ready outputs: process maps, experiment plans, and goal-oriented recommendations.

Case studies

Anonymized outcomes

Representative engagements demonstrate how we deliver decision-ready outcomes while maintaining strict client confidentiality.

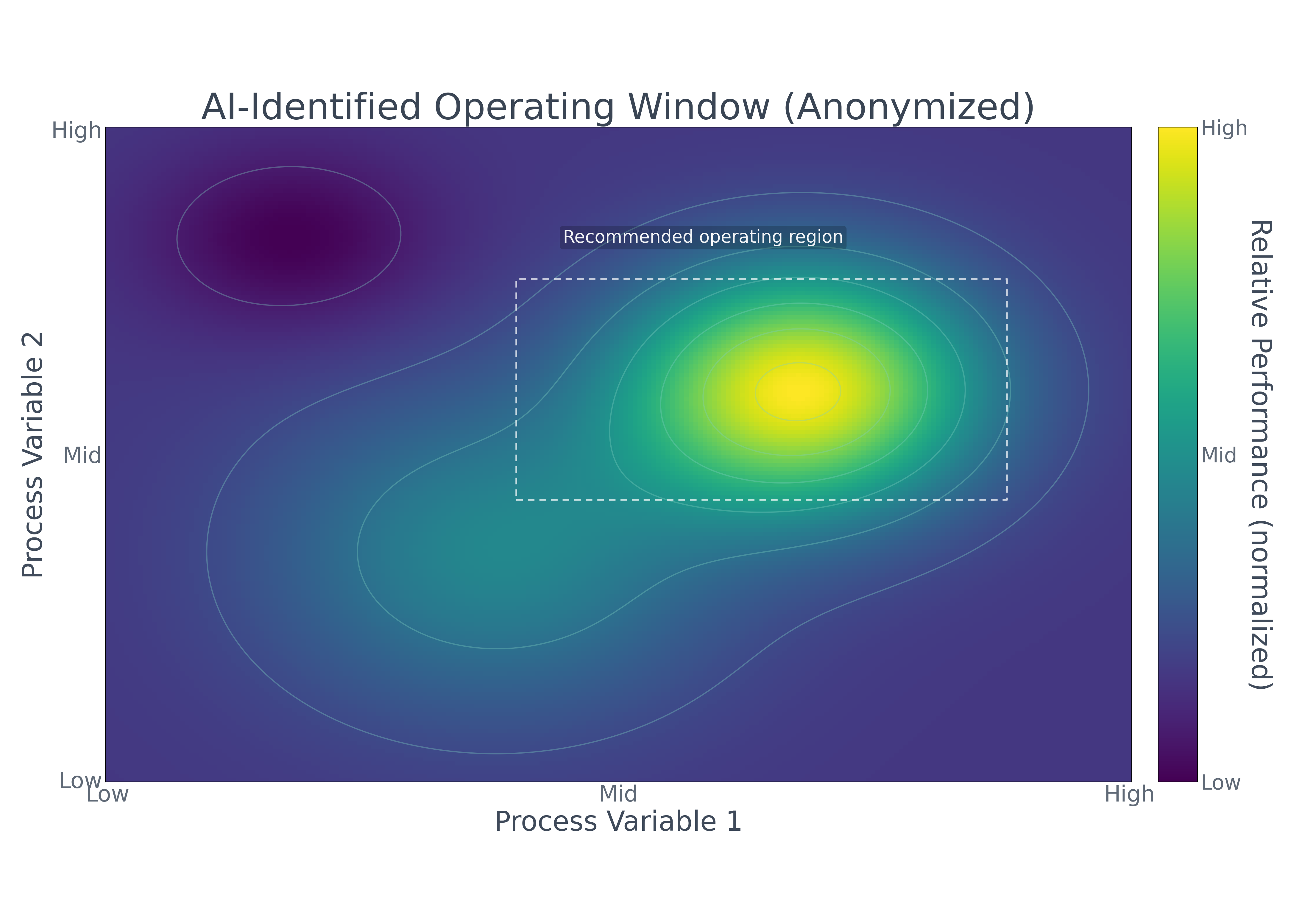

Process Map Exploration

Identified stable operating regions and trade-offs from sparse experimental coverage.

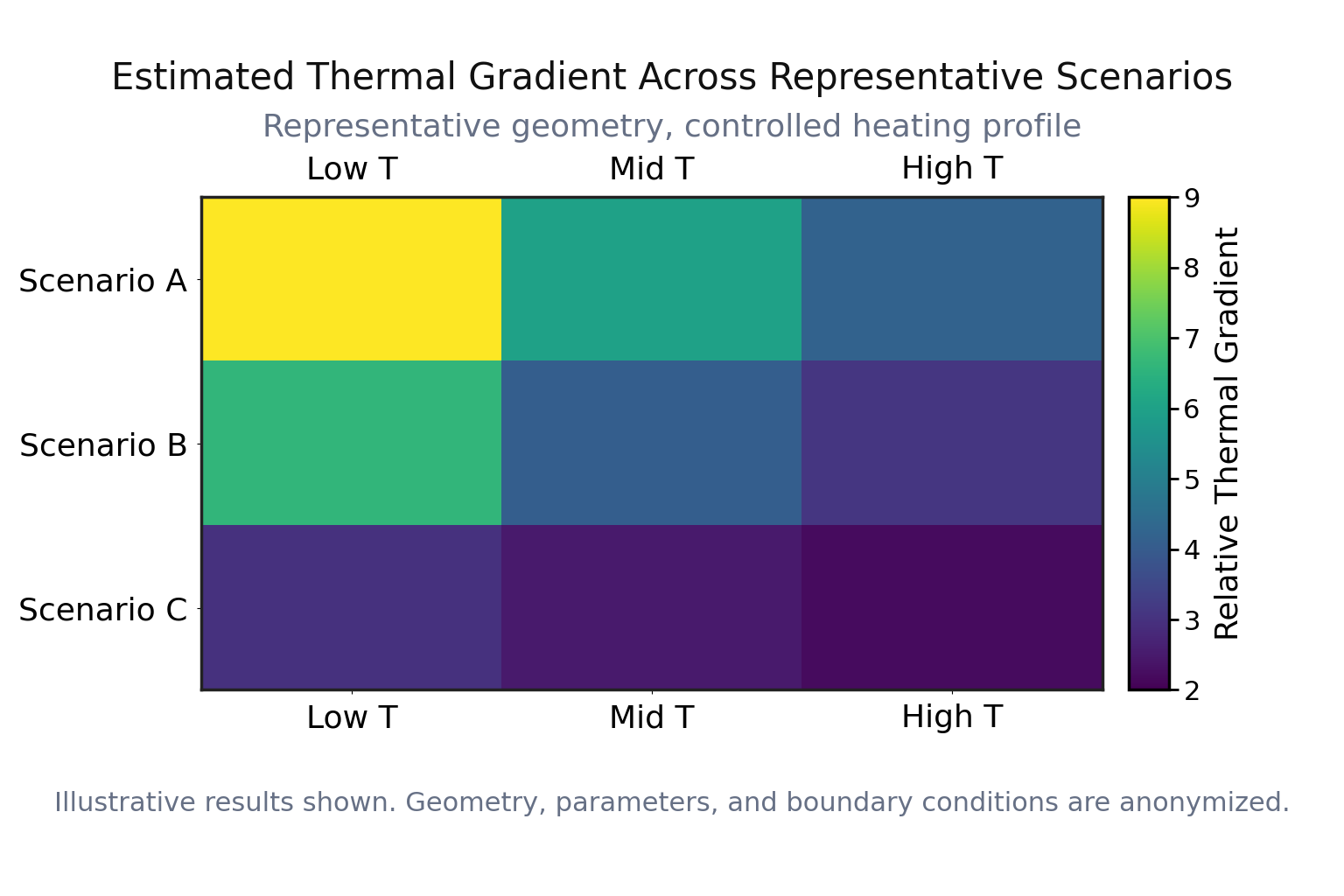

Thermal Field Simulation

Evaluated thermal gradients to inform process and equipment design decisions.

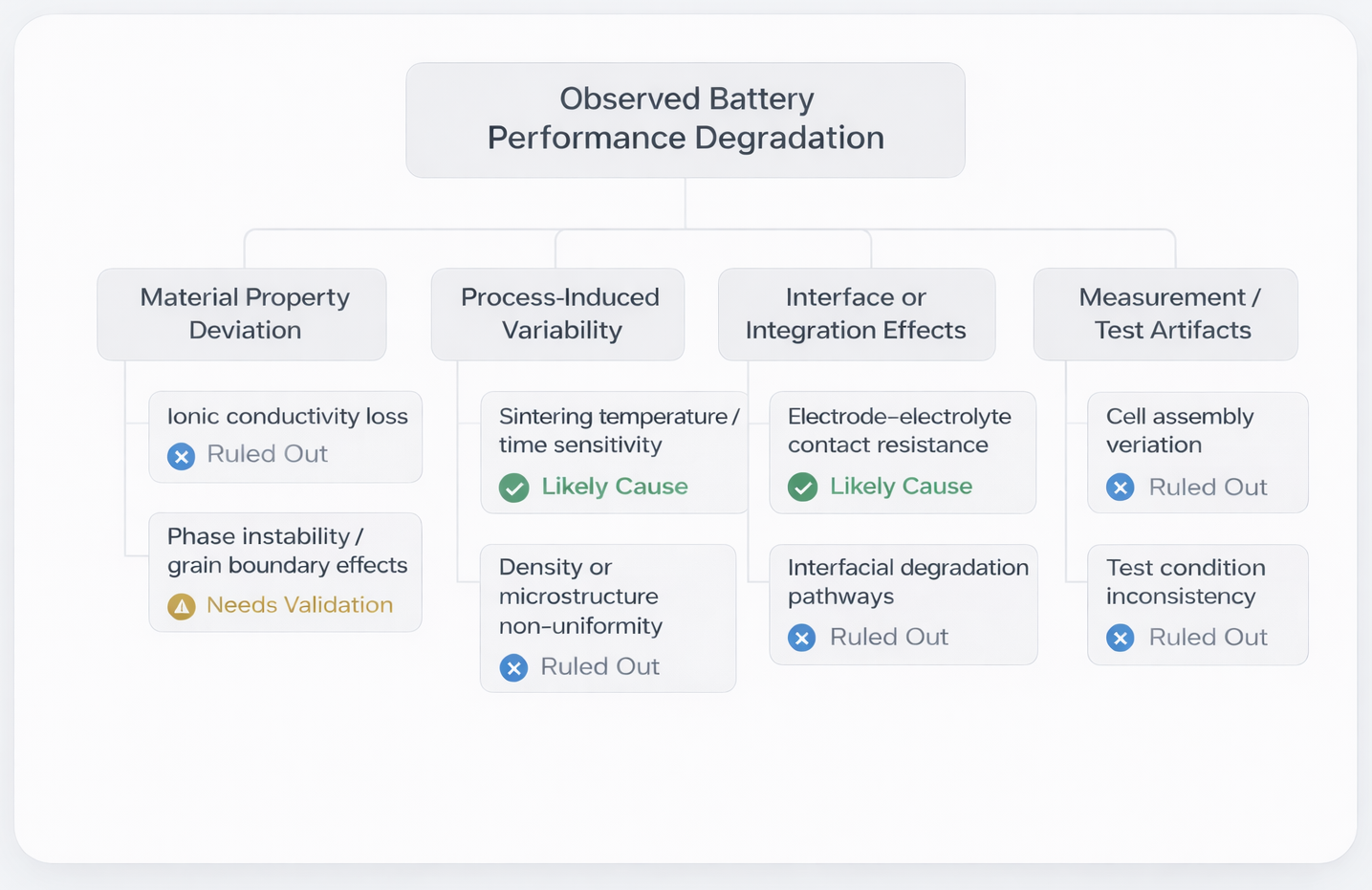

Root Cause Triage

Prioritized high-likelihood hypotheses and aligned validation steps across teams

Engagement models

Ways to work together

Choose the collaboration depth that fits your timeline, stakeholder cadence, and internal bandwidth.

Exploration Sprint

Rapid scoping with initial models and decision framing.

- Scope brief

- Initial DOE

- Decision memo

Deep Dive

End-to-end decision analysis with iterative stakeholder alignment.

- Decision analysis package

- Operating trade-offs & constraints

- Executive readout

Ongoing Advisor

Embedded decision support and continuous optimization support.

- Monthly readout

- Updated risk log

- Roadmap updates

About

Founder & Principal Consultant

Boconix Tech is led by a PhD-level materials scientist with hands-on experience in battery and semiconductor process development. The focus is pragmatic: clarifying assumptions, quantifying risk, and delivering decisions teams can act on.

Bringing PhD-level judgment to materials characterization, process window engineering, and manufacturability decisions for advanced energy and electronics programs.

Contact

Let’s discuss your decision needs

Share a few details and we will respond with next steps. We keep conversations NDA-friendly.

- A brief proposed approach (1–2 options)

- Expected inputs or data needed

- Suggested timeline and deliverables